Braided Tinned Flat Tapes Manufacturer in India

Yeshwant Wires is one of the leading Braided Tinned Flat Tapes manufacturers in India, delivering premium-quality tinned copper braids designed for superior performance in earthing, grounding, busbar connections, and electrical bonding applications. Our braided flat tapes ensure exceptional conductivity, corrosion resistance, and flexibility, providing unmatched reliability for mission-critical electrical installations.

Engineered with 99.99% electrolytic grade copper and uniform tin coating, these braided tapes offer excellent current-carrying capacity, oxidation protection, and long service life in demanding environments. Each product is tested to meet or exceed IS 8130, IEC 60228, ASTM B33, and ASTM B172 international standards. Available in various widths, thicknesses, and current ratings, our braided tinned flat tapes are ideal for both industrial power systems and commercial electrical installations.

What are Braided Tinned Flat Tapes?

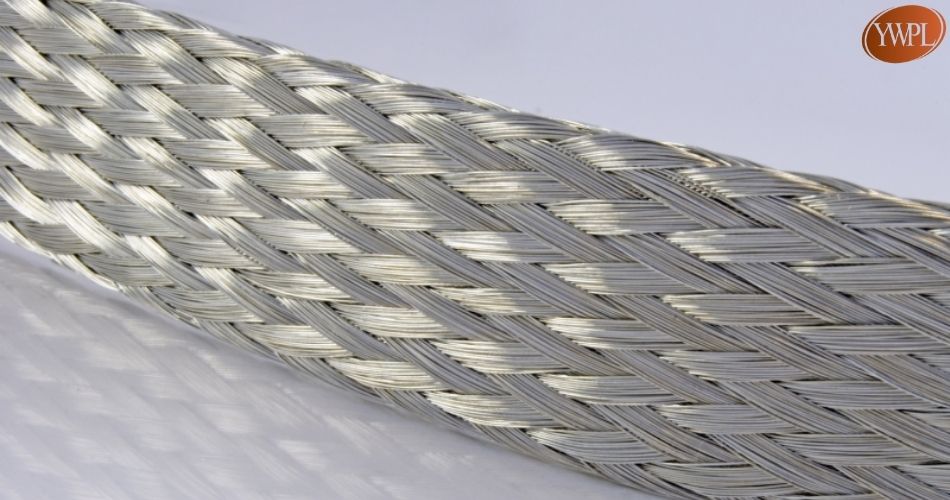

Braided Tinned Flat Tapes are flexible electrical conductors made by interlacing fine tinned copper wires into a flat braided structure. The tin coating provides superior protection against corrosion and oxidation, making these tapes essential for earthing, grounding, electrical continuity, and flexible connections in industrial and commercial electrical systems.

Unlike rigid conductors, braided flat tapes offer exceptional flexibility, making them ideal for applications involving vibration, movement, or thermal expansion. They are widely used in switchgear panels, transformers, busbars, automotive systems, renewable energy installations, and lightning protection where reliable electrical performance and environmental resistance are critical.

Key Features & Technical Advantages

- Superior Conductivity: 99.99% pure copper ensures maximum current flow with minimal resistance.

- Corrosion Protection: Uniform tin coating prevents oxidation and extends operational life.

- Exceptional Flexibility: Braided construction allows easy installation in tight spaces and moving parts.

- Enhanced Surface Area: Flat design improves heat dissipation and current distribution.

- High Current Capacity: Supports 10A to 5000A+ depending on braid cross-section.

- Vibration Resistant: Ideal for applications with mechanical stress or constant movement.

- Temperature Resilient: Reliable performance from -40°C to +150°C.

- Customizable Dimensions: Width, thickness, and braid density tailored to specific requirements.

- Standards Compliant: Meets IS, IEC, ASTM, and BS international quality standards.

Comprehensive Technical Specifications

| Property | Specification | Significance |

|---|---|---|

| Conductor Material | High-Conductivity Electrolytic Copper (Individually Tinned Strands) | The copper provides high current capacity, while the tinning provides crucial corrosion and oxidation resistance, ensuring stable, long-term conductivity. |

| Voltage Grade | Low to Medium Voltage (Used mainly for high current/bonding) | Primarily used for equipotential bonding and earthing, meaning the conductor operates at low voltage relative to ground, but the surrounding equipment may be up to medium voltage. |

| Operating Temperature | -40°C to +150°C (Material Dependent) | The high rating is necessary for safely dissipating heat generated by continuous high current or large fault/short-circuit currents common in grounding systems. |

| Construction | Flat Braid (Woven from Fine Tinned Copper Wires) | Defining Feature. The woven flat shape provides extreme flexibility to handle vibration and thermal movement, crucial in busbar systems and switchgear assemblies. |

| Corrosion Resistance | Excellent | The tin layer prevents the fine copper strands from reacting with moisture, industrial gases, and salts, which is vital for use in coastal areas or chemical plants. |

| Termination Ends | Pressed or Welded Copper Lugs/Ferrules | Requires a secure, gas-tight termination to maintain low resistance. Tinned surfaces improve solderability and contact reliability. |

| Key Function | Flexible Grounding, Earthing Jumpers, and Bonding Straps | Used extensively in environments where longevity in harsh conditions and compensation for movement are both required. |

Types of Braided Tinned Flat Tapes

Single Layer Braids

Standard flat braids for general earthing and bonding applications with moderate current requirements.

Multi-Layer Braids

Heavy-duty braids with multiple layers for high current capacity in power distribution and busbar connections.

Wide Format Tapes

Extra-wide braids (50mm-150mm) for transformer connections and large busbar linkages.

Custom Braids

Application-specific designs with special dimensions, terminals, or end fittings as per requirement.

Applications & Industries

Earthing & Grounding

Electrical panels, equipment grounding, safety earthing systems

Busbar Connections

Flexible busbar linkages, expansion joints, movable connections

Transformers

Neutral earthing, winding connections, tap changers

Switchgear Panels

Panel bonding, door connections, circuit breaker links

Automotive & Railway

Vehicle grounding, battery connections, electrical bonding

Renewable Energy

Solar array bonding, wind turbine grounding, inverter connections

Lightning Protection

Down conductor connections, air terminal bonding, earthing strips

Welding Equipment

Flexible ground connections, electrode holders, cable assemblies

Battery Systems

UPS interconnections, battery bank linking, power backup systems

Manufacturing Excellence & Quality Assurance

Yeshwant Wires manufactures braided tinned flat tapes using advanced precision braiding machines and automated tin-plating processes. Our ISO 9001:2015 certified manufacturing facility ensures consistent quality through rigorous testing at every production stage.

Quality Testing

Every batch undergoes electrical conductivity, tensile strength, flexibility, and corrosion resistance testing.

Tin Coating Quality

Uniform 3-5 micron tin plating verified through thickness gauging and salt spray testing.

Dimensional Accuracy

Precision braiding ensures consistent width, thickness, and braid density throughout the tape length.

Compliance Certification

Test certificates provided with every order confirming conformity to international standards.

Why Choose Yeshwant Wires?

Trusted Manufacturer

Recognized Braided Tinned Flat Tapes manufacturer in India with decades of expertise in copper products.

Custom Engineering

Tailored solutions with specific widths, thicknesses, terminal attachments, and end configurations.

Premium Materials

Made with 99.99% pure copper and high-quality tin coating for maximum performance and longevity.

Global Standards

Complies with IS, IEC, ASTM, and BS international quality and safety standards.

Competitive Pricing

Factory-direct pricing with volume discounts and flexible payment options.

Nationwide Supply

Fast delivery across India with export capabilities to international markets.