Instrumentation Cables

Yeshwant Wires is a trusted Instrumentation Cables manufacturer in India, specializing in signal and data transmission solutions for automation, process control, oil & gas, power, and industrial sectors. Our cables ensure precise and interference-free communication between control systems and field instruments, ensuring accurate monitoring and control.

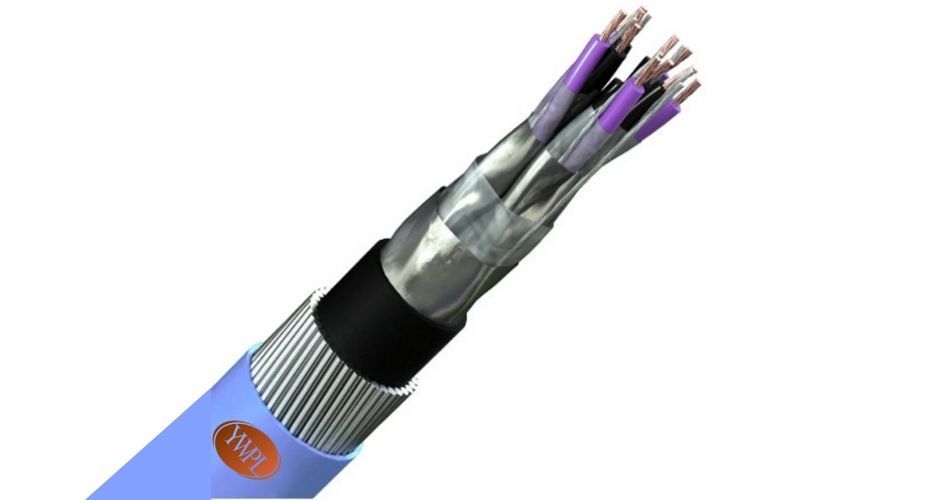

Designed with tinned or bare copper conductors and advanced shielding options, these cables deliver exceptional signal integrity, EMI protection, flexibility, and long service life. They comply with IS, BS, and IEC standards and are available in both armoured and unarmoured configurations to suit diverse applications.

Description

Instrumentation Cables are specialized control cables used for transmitting low-voltage signals in industrial automation systems. They are engineered to provide reliable communication between sensors, transmitters, and control panels by minimizing electrical interference and ensuring data accuracy.

These cables are extensively used in process industries, refineries, petrochemical plants, power stations, and manufacturing units where dependable signal transmission is critical for operational safety and performance.

Key Features & Advantages

- Low Signal Loss: Designed for accurate and stable data transmission.

- Superior EMI Protection: Shielded with aluminium foil or copper braid to prevent interference.

- High Temperature Resistance: Suitable for both indoor and outdoor installations.

- Oil & Chemical Resistant: Outer sheath resists corrosion and harsh industrial conditions.

- Flexible Construction: Simplifies installation through conduits or cable trays.

- Custom Configurations: Single pair, multi-pair, armoured, or unarmoured options available.

- Complies with Global Standards: IS 1554, BS 5308, IEC 189, and EN 50288.

Technical Specifications

| Property | Specification | Significance |

|---|---|---|

| Conductor Material | Annealed Bare / Tinned Copper (Solid or Stranded) | Ensures high conductivity. Tinned copper provides crucial corrosion resistance for damp or chemically active industrial settings. |

| Insulation | PVC / PE / XLPE / FRLS / HR PVC | Offers flexibility to meet thermal and chemical demands. XLPE (Cross-linked) and HR PVC provide higher temperature tolerance; FRLS (Flame Retardant Low Smoke) enhances fire safety. |

| Core Identification | Number Coded or Colour Coded as per Standards | Essential for installation and maintenance to correctly trace and connect circuits (e.g., pairs, triads). |

| Shielding | Aluminium Mylar Tape / Copper Braid / Foil Shield | Critical for protecting sensitive, low-level signals from Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI), ensuring measurement accuracy. |

| Armouring | GI Wire / Steel Tape Armoured (optional) | Provides mechanical protection against crushing, impact, and rodent damage, often required for direct burial or exposed plant routing. |

| Sheath | PVC / FRLS / LSZH (UV & Oil Resistant) | Protects the core bundle from environmental factors. LSZH (Low Smoke Zero Halogen) is key for indoor safety; UV & Oil Resistance is mandatory for chemical and outdoor installations. |

| Voltage Grade | Up to 1100 V | Rated for power-level voltages, allowing safe routing in common trays or conduits with medium-voltage power cables, though the signals transmitted are low voltage. |

| Operating Temperature | -15°C to +85°C | Defines the thermal stability range, indicating suitability for various demanding process environments. |

| Standards | IS 1554 / IS 694 / IS 8130 | Compliance ensures the cable meets international requirements for construction, performance, and testing of industrial control and instrumentation cables. |

Applications

Instrumentation Cables are used in refineries, power plants, automation systems, and control rooms for signal transmission between field devices and control systems. They are suitable for connecting PLCs, DCS panels, transmitters, sensors, and measurement instruments.

Manufacturing & Quality Assurance

At Yeshwant Wires, every instrumentation cable is produced using advanced extrusion, twisting, shielding, and armouring processes for precision and reliability. Cables undergo stringent testing for continuity, insulation resistance, capacitance, attenuation, and flame retardancy under ISO certified quality systems.

Why Choose Yeshwant Wires for Instrumentation Cables?

Industry Leadership

Premier Instrumentation Cable manufacturer in India with 8+ years of expertise.

Custom Solutions

Tailored cable designs for specific protocols, environments, and performance requirements.

Premium Materials

99.99% pure copper conductors and high-grade insulation for maximum performance.

Global Standards

Full compliance with IS and ISO/IEC international standards.

Competitive Pricing

Factory-direct pricing with no compromise on quality or performance.

Pan-India Delivery

Fast, reliable delivery across all major cities and industrial hubs in India.

Industries We Serve

Industry Leadership

Premier Instrumentation Cable manufacturer in India with 8+ years of expertise.

Custom Solutions

Tailored cable designs for specific protocols, environments, and performance requirements.

Premium Materials

99.99% pure copper conductors and high-grade insulation for maximum performance.

Global Standards

Full compliance with IS and ISO/IEC international standards.

Competitive Pricing

Factory-direct pricing with no compromise on quality or performance.

Pan-India Delivery

Fast, reliable delivery across all major cities and industrial hubs in India.

We supply Instrumentation Cables to diverse industries such as oil & gas, petrochemicals, pharmaceuticals, power generation, and infrastructure. Our solutions are tailored for high performance, safety, and reliability in mission-critical applications.